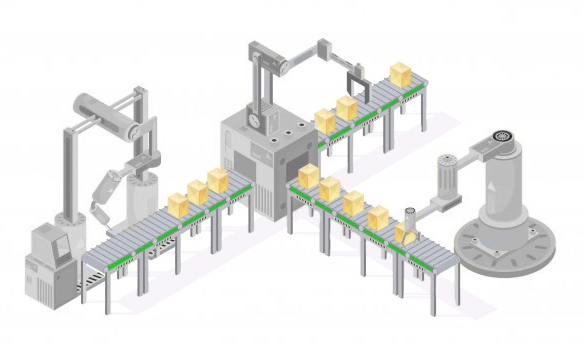

Conveline's Material Handling & Industrial Conveyors are designed to handle all stages of the manufacturing process, from production and assembly through inspection and packing.

With an array of models available, you'll find a conveyor belt material handling solution for small components and large boxes, for straight or curved paths, and for on the ground or overhead. In addition to our standard conveyor offerings, Conveline offers custom material handling and industrial conveyor solutions designed for your unique space and business needs.

Conveyors improve efficiency, increase output, reduce costs and, in general, keep things running smoothly.

Conveline Material Handling & Industrial Conveyors Are Built for Peak Efficiency and Productivity

As material handling and industrial conveyors transport products through a facility or production process, they reduce footprint by maximizing space, increase uptime, improve efficiency, enhance accuracy, lower production and labour costs as well as boost worker safety.

With an automated material handling and industrial solution from Conveline's complete line of industrial belted, modular belt and flexible chain conveyors in place, your business can speed up cumbersome processes or even reallocate your employees from tedious tasks to higher-priority ones. With the increased accuracy of automation, you'll improve cost efficiency and reduce waste.

These gains are the result of increased uptime and improved product movement, flow and quality. Another way conveyors can benefit your bottom line, especially those designed for tight spaces such as FlexMove, is that you can still find ways to increase your production capacity even with limited space.

Workplace safety is also improved in a few ways. Reducing or eliminating the need for lift trucks, for example, lessens the chance for collisions or accidents on the floor. Also, leaving the heavy lifting for conveyors literally takes a load off your operators, preventing injuries related to lifting or pushing.

Custom Material Handling & Industrial Conveyors

As part of our Engineered Solutions Group, Conveline's custom material handling and industrial conveyor offerings are designed and manufactured to meet your specific workflow needs. Conveline offers an array of customizable, automated solutions to fit all stages of your process or spaces of all sizes, including inspection and testing, elevations and line egress, index and positioning, depositing and rejects, diverting and sorting, product flow and control, and merging.

Conveline's expert team will ask the right questions in order to understand your business goals and challenges, and then our custom material handling and industrial solutions team, comprising drafters, designers and electrical and mechanical engineers, will get to work.

To cite an example, a pharmaceutical company wanted to increase its efficiency. At the time, pharmacy technicians manually carried totes between their filling stations and the verification and packing stations. This was not the best use of these employees' time. After consulting with Conveline, the result was a three-level tote handling system that allowed prescriptions to move through the facility automatically, with operators positioned at strategic locations.

Our custom material handling and industrial conveyor offerings come with the same installation, training and maintenance services as our standard lines.